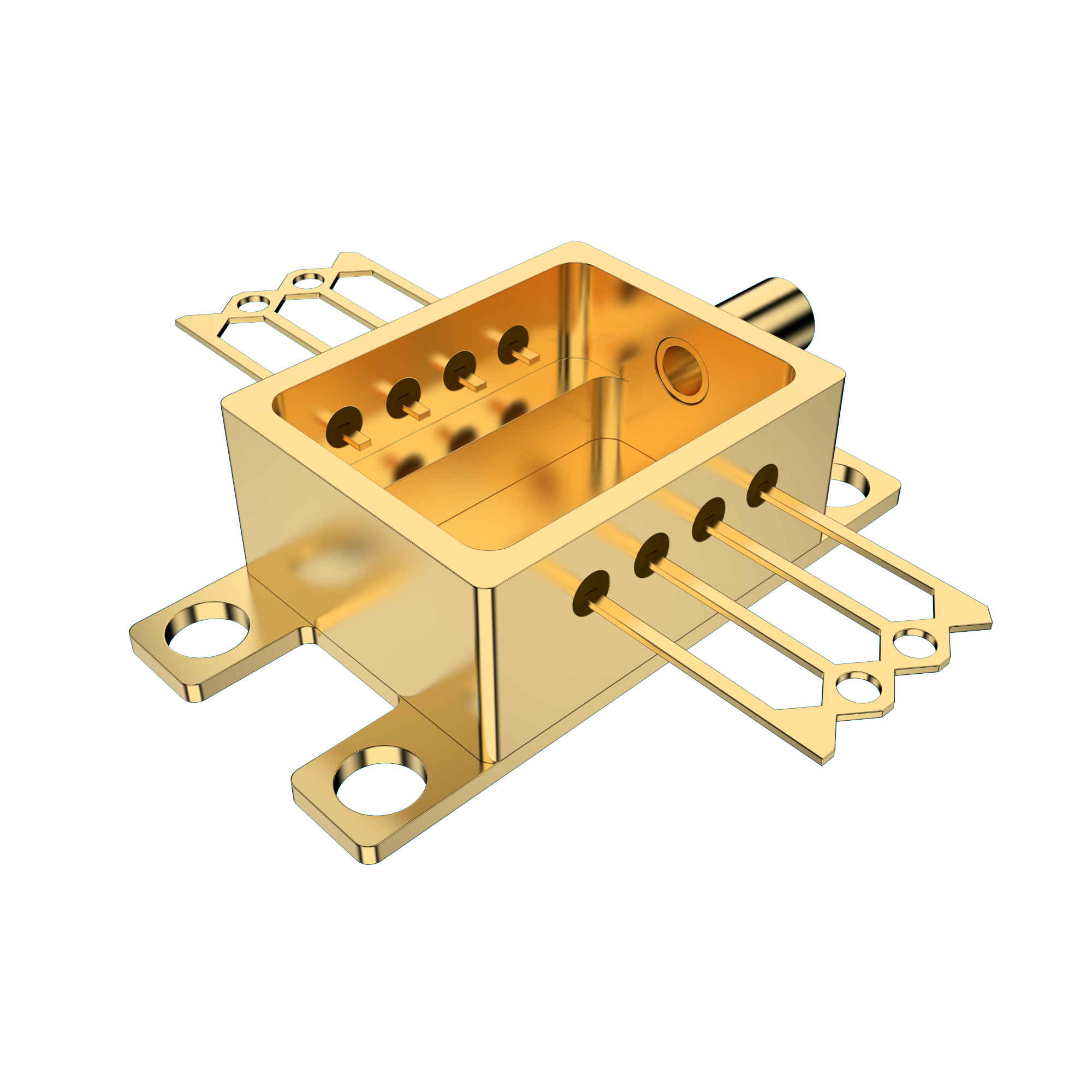

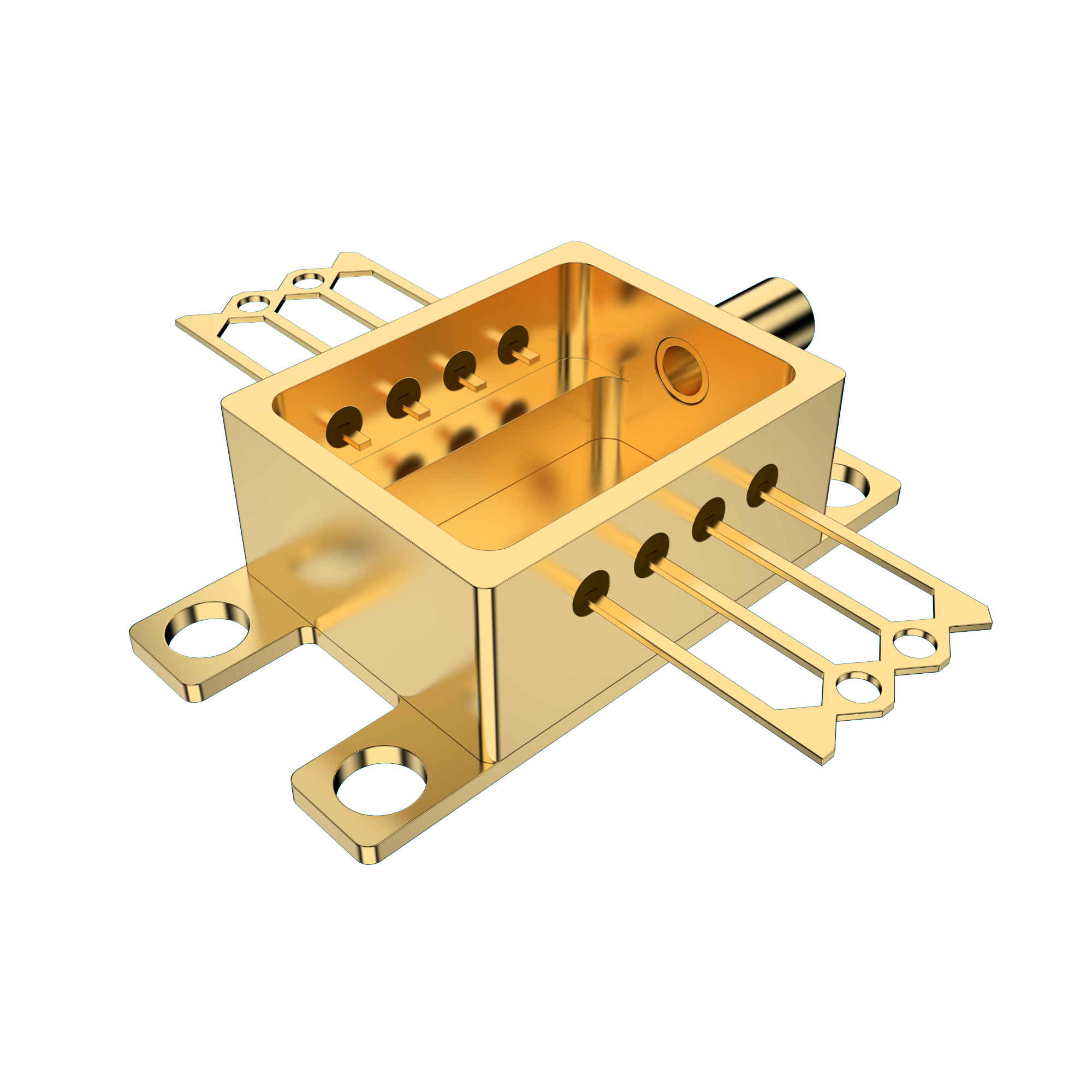

In modern high-precision applications, from telecommunications to aerospace, the reliability and stability of laser systems are critical. At Rizhao Xuri Electronics Co., Ltd., we take pride in our advanced Laser Diode Butterfly Packages, designed to ensure long-lasting, stable performance under demanding conditions. Since our establishment in 2001, our company has been committed to developing innovative, high-tech solutions that cater to the most challenging industrial requirements. This blog explores the mechanisms within the Laser Diode Butterfly Package that guarantee stable and reliable operation, focusing on its thermal, mechanical, electrical, and monitoring features.

What "Stability" Means for Laser Systems

In laser systems, "stability" refers to maintaining consistent performance over time, ensuring that the laser's output—whether in terms of power, wavelength, or beam quality—remains predictable and reliable. For industries like telecommunications, defense, and medicine, this stability is crucial. Variations in a laser’s output can result in poor performance, compromised safety, and potential system failure. Therefore, when designing laser diode systems, ensuring stability is a top priority, and the Butterfly Package is engineered with several key features to meet this demand.

The Consequences of Instability in Critical Systems

Laser systems are often integrated into mission-critical operations, such as in aerospace, medical devices, and telecommunication infrastructure. Any instability—be it in wavelength, power, or mechanical properties—can have dire consequences. For instance, instability in a laser’s output can lead to signal degradation in optical communication systems, result in inaccurate measurements in medical equipment, or cause failures in sensors used for military applications. Therefore, the Laser Diode Butterfly Package is designed to mitigate these risks and ensure that the laser maintains high levels of operational stability, regardless of external conditions.

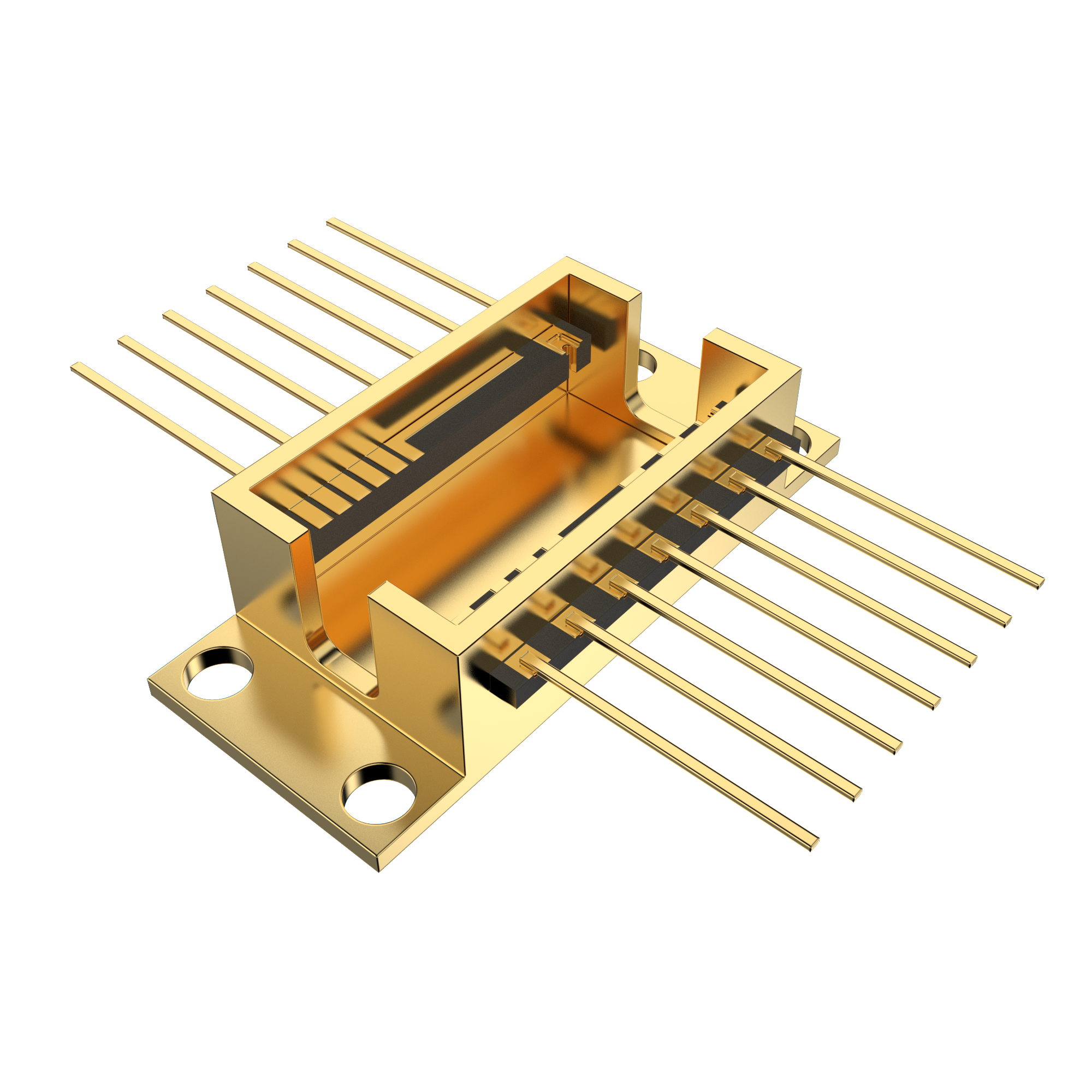

Thermal Stability through TEC Integration

One of the most significant challenges in ensuring the stability of laser diodes is temperature fluctuations. Laser diodes are highly sensitive to temperature changes, which can cause shifts in their emission wavelength and output power. To address this, the Laser Diode Butterfly Package integrates a Thermoelectric Cooler (TEC) for active thermal management.

Active Cooling Mechanism Explained

The TEC is an active cooling device that maintains a constant operating temperature for the laser diode. By transferring heat away from the laser and into the surrounding environment, it helps regulate the temperature to optimal levels, preventing overheating and thermal runaway. This thermal control ensures that the laser diode operates at a stable temperature, enhancing its overall performance and longevity.

Impact on Spectral and Power Stability

Temperature-induced changes in the laser’s performance can cause fluctuations in both spectral output and power levels. The integrated TEC helps prevent these fluctuations by keeping the diode’s temperature stable, ensuring that the laser’s output remains consistent. This is especially important for applications where precise wavelength and power control are essential.

Mechanical Isolation and Hermetic Sealing

Another critical aspect of the Laser Diode Butterfly Package is its ability to protect the laser diode from physical stressors, such as vibration and shock. In many industrial applications, lasers are exposed to harsh mechanical conditions, such as in mobile platforms, industrial machinery, or transportation systems. These conditions can result in misalignment, damage to the diode, or instability in its operation.

How Shock/Vibration Resistance is Built In

To address these challenges, the Butterfly Package incorporates mechanical isolation features, such as shock-resistant materials and robust housing. These design elements absorb and dampen vibrations and shocks, preventing them from reaching the sensitive laser diode. The result is a stable, vibration-resistant system that continues to perform accurately even in challenging environments.

Benefits for Mobile and Industrial Uses

The ability to withstand vibrations and mechanical stress is especially beneficial for mobile applications, such as satellites, autonomous vehicles, and drones, as well as industrial systems, where robust and reliable operation is crucial. The Butterfly Package's resistance to mechanical shocks and vibrations ensures that the laser diode remains stable and operational even in the most demanding conditions.

Electrical Shielding and EMI Protection

Electromagnetic interference (EMI) is another significant challenge for laser systems. Unwanted electrical noise can affect the laser’s performance, causing fluctuations in output power or damaging the sensitive components. To counteract this, the Laser Diode Butterfly Package includes effective shielding against electrical noise.

Design Against Electrical Noise

The package’s design incorporates various strategies to prevent EMI, including the use of conductive materials and specialized coatings that block external electrical noise. This ensures that the laser diode operates without interference from surrounding electronic components, maintaining its stability and reliability.

Filtering and Grounding Methods

In addition to shielding, the Butterfly Package also includes advanced filtering and grounding methods that help eliminate any residual electrical noise. By ensuring that the laser is isolated from unwanted electrical signals, these methods further enhance the operational stability of the system.

Monitoring Feedback Components

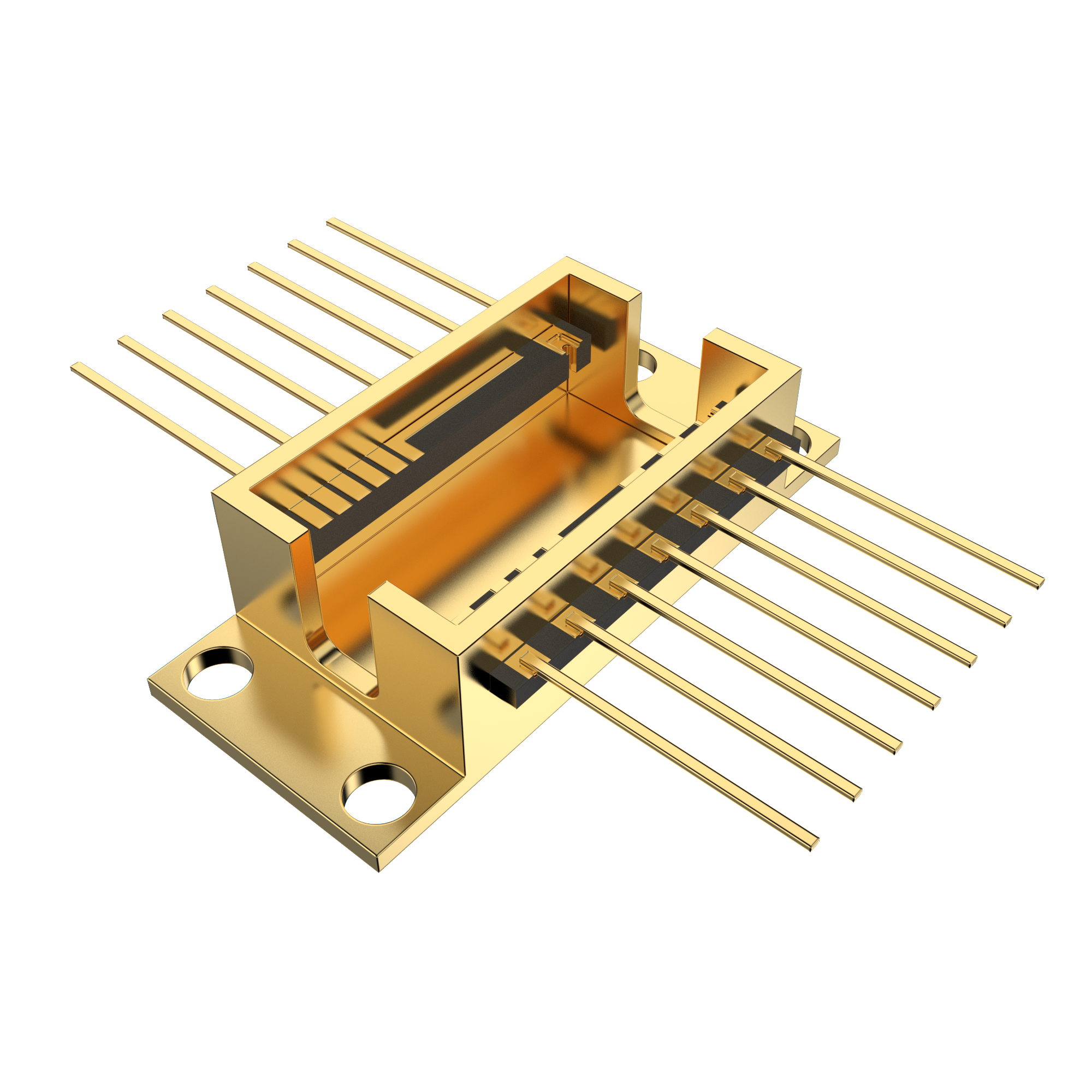

One of the standout features of the Laser Diode Butterfly Package is its real-time monitoring capabilities. Through the integration of feedback components like photodiodes and thermistors, the package continuously monitors the laser’s operational conditions.

Use of Photodiodes and Thermistors for Closed-Loop Control

Photodiodes measure the output power and wavelength of the laser, while thermistors track the temperature of the diode. These components work together to ensure that the laser’s performance stays within desired parameters. If any parameter deviates from the preset range, the system can adjust in real time to correct it.

Real-Time Monitoring for Stability Assurance

The closed-loop control system provides constant feedback, allowing the laser to self-correct and maintain its optimal performance. This real-time monitoring is essential for ensuring that the laser remains stable throughout its operational life, even under varying environmental conditions.

Real-World Performance in Harsh Environments

The Laser Diode Butterfly Package is designed to excel in harsh environments, such as those found in aerospace, defense, and outdoor telecommunications.

Aerospace, Defense, and Outdoor Telecom Case Contexts

In aerospace and defense, where reliability and stability are non-negotiable, the Butterfly Package ensures that laser diodes continue to operate flawlessly in extreme temperatures, vibrations, and other challenging conditions. Similarly, in outdoor telecom applications, where lasers are exposed to the elements, the package’s robust thermal management and mechanical isolation capabilities provide uninterrupted performance.

Conclusion

The Laser Diode Butterfly Package is a critical component for ensuring the stable operation of laser systems in a variety of industries. By integrating advanced thermal management, mechanical isolation, electrical shielding, and real-time monitoring features, our package guarantees that laser diodes remain stable and reliable even in the most demanding environments. At Rizhao Xuri Electronics Co., Ltd., we are proud to offer this cutting-edge solution to meet the needs of industries where stability and performance are paramount.

For more information on how our Laser Diode Butterfly Package can enhance your systems’ reliability, please feel free to contact us. Our team is ready to assist you in choosing the right solution for your mission-critical applications.

English

English