Laser diodes are widely used in various applications, from telecommunications and healthcare to industrial manufacturing, thanks to their versatility and precision. However, mounting a laser diode correctly is crucial to ensure optimal performance and longevity. The mounting process involves several factors that directly impact the diode’s functionality, including thermal management, alignment, and electrical connection. This guide will cover the essential do's and don'ts when mounting a laser diode, helping you avoid common pitfalls and achieve the best results.

Why Proper Mounting of Laser Diodes is Crucial

Understanding the Laser Diode and Its Applications

Laser diodes are semiconductor devices that emit light when current passes through them. They are found in numerous applications, such as fiber optic communication, barcode scanners, and medical equipment like laser surgeries. The performance of these devices relies heavily on their installation and alignment. A well-mounted laser diode ensures effective light emission and minimizes energy loss, while improper mounting can cause alignment issues, overheating, and reduced lifespan.

Consequences of Incorrect Mounting

Incorrect mounting of a laser diode can lead to several detrimental effects. For example:

Thermal Management Issues: A poorly mounted diode may not dissipate heat effectively, leading to thermal runaway, which can damage the diode permanently.

Alignment Problems: Misalignment between the laser and its fiber coupling can result in inefficient light transmission.

Electrical Damage: A weak or improperly connected electrical contact can lead to short circuits or inconsistent power delivery, compromising the diode's performance.

Do’s of Mounting a Laser Diode

Select the Right Mount for Your Application

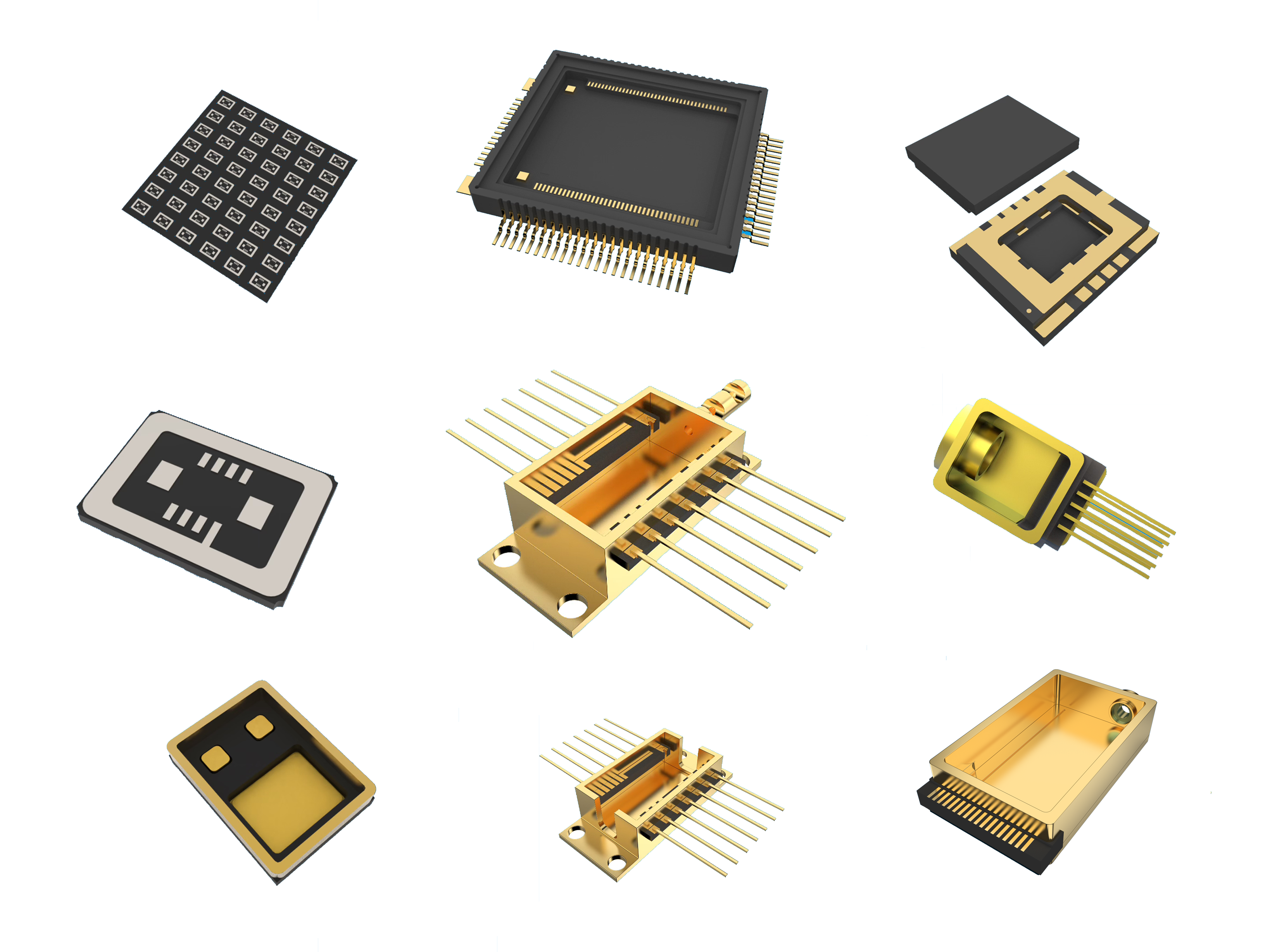

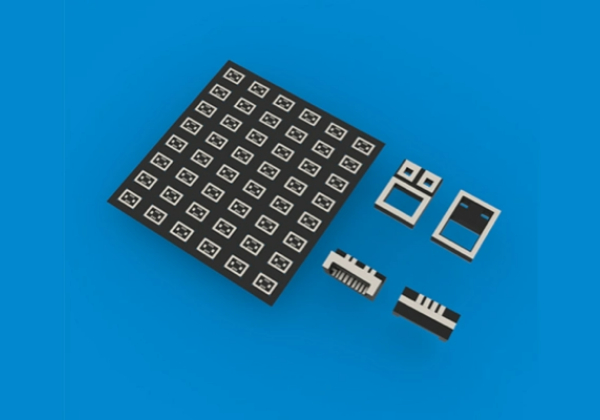

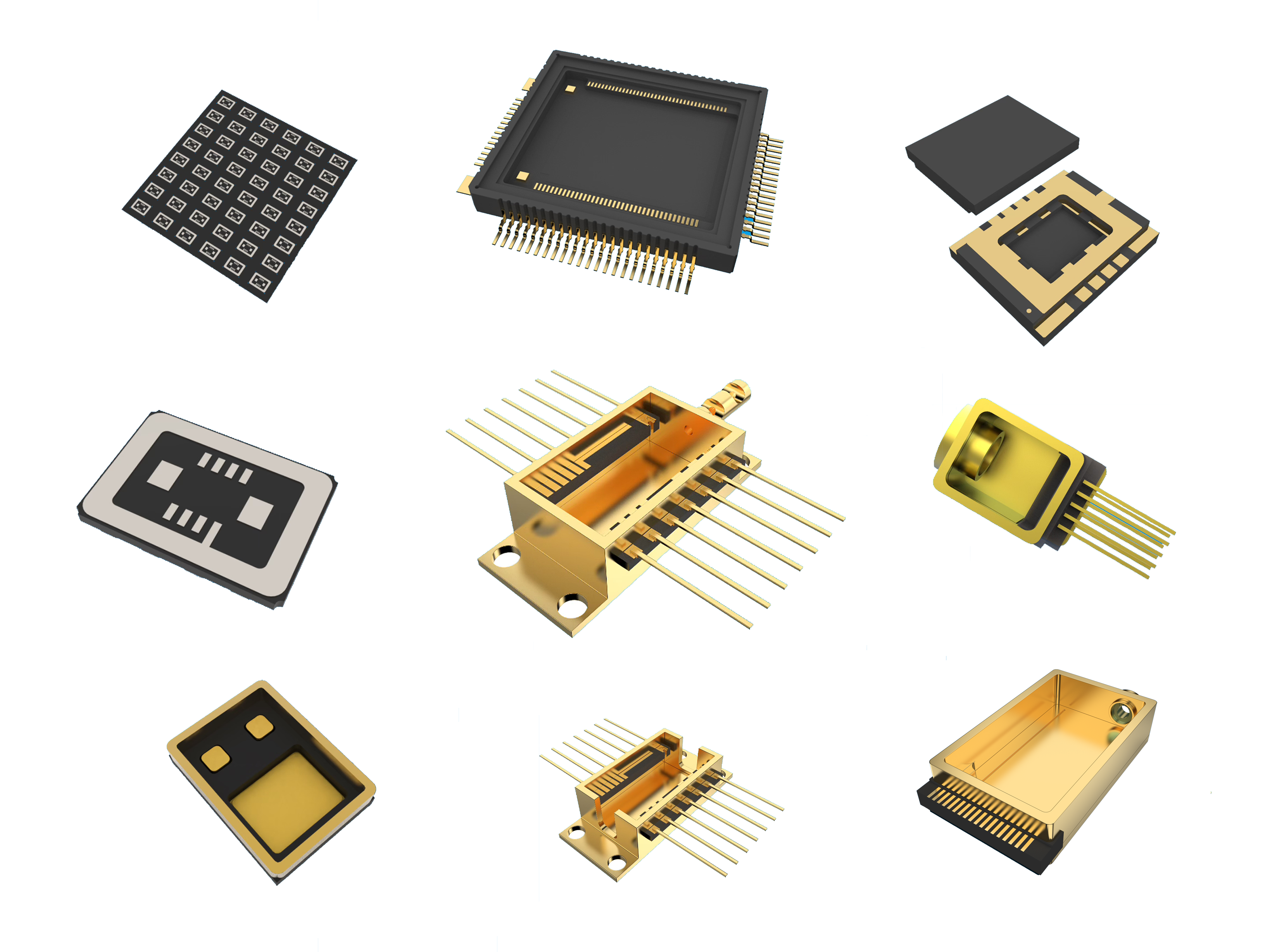

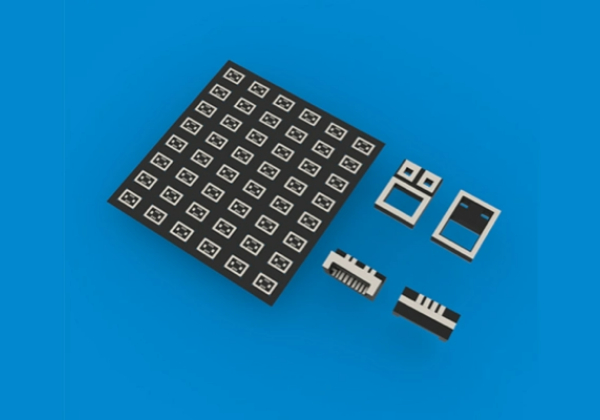

Different laser diodes have different mounting requirements based on their shape, power output, and application. For example, butterfly packages, commonly used in telecom, require specialized mounts for stable, vibration-free operation. Similarly, TO-can lasers may require custom mounting solutions. Understanding the type of laser you are using and selecting an appropriate mount will ensure its optimal performance and prevent mechanical stress.

Unpack Carefully and Let It Reach Thermal Equilibrium

Before handling the laser diode, let it sit undisturbed for several hours after unpacking. This ensures that the diode reaches thermal equilibrium, preventing thermal shock that could damage the components. When handling the diode, always wear clean gloves and use tweezers. Keep your workspace free of contaminants like dust and airborne particles, as even minor debris can damage the sensitive laser facet or wire bonds.

Ensure Flatness of the Mounting Plate

The flatness of the mounting surface is a critical factor when mounting a laser diode, especially for fiber-coupled lasers. An uneven surface can cause the laser package to bend, which leads to misalignment and poor light coupling efficiency. It can also cause inconsistent thermal contact, resulting in poor heat dissipation. Use precision tools to ensure that the mounting plate is perfectly flat before securing the laser diode.

Use the Correct Hardware for Mounting

It’s important to select the correct screws, washers, and bolts for mounting the laser diode. Using undersized screws can lead to inadequate compression and a poor connection to the mounting surface, affecting thermal management. Conversely, oversized screws can cause mechanical interference or damage to the diode's structure. Ensure that screws are of the correct length—too long, and they might damage underlying components like Peltier coolers; too short, and they may fail to secure the diode properly.

Apply Grease (When Necessary)

Grease plays a key role in enhancing the thermal contact between the laser diode and its mounting surface, especially in high-power devices. A thin layer of non-silicone grease can help improve heat dissipation, keeping the diode at a safe operating temperature. For low-power devices (under 1-2 watts), grease is usually not necessary. Be careful not to overapply the grease, as excess grease can cause contamination or improper heat transfer.

Tighten Screws Properly

When securing the laser diode to the mount, avoid over-tightening the screws. Over-tightening can damage the mounting threads or warp the laser package, leading to permanent damage. Use a crisscross pattern to tighten the screws, ensuring even pressure distribution across the diode. If torque specifications are provided by the manufacturer, follow them to avoid any issues with compression.

Secure the Electrical Connection

The electrical connection to the laser diode should be made with the appropriate connector and wire size to ensure a reliable power supply. A poor connection can cause overheating, power loss, or even diode failure. Some mounts come with built-in electrical connectors designed specifically for laser diodes, ensuring a high-quality, solderless connection. Always check the compatibility of the connector before making the connection.

Don’ts of Mounting a Laser Diode

Don’t Use the Wrong Mount or Hardware

Using incompatible mounts or hardware can lead to poor alignment, mechanical stress, and even damage to the laser diode. Always use mounts that are specifically designed for the laser diode type you are working with. Using mismatched screws or mounts can compromise the laser’s functionality and lead to costly repairs.

Don’t Rush the Unpacking Process

Unpacking a laser diode too quickly or without allowing it to stabilize to room temperature can lead to thermal shock, which might damage sensitive components. Always follow manufacturer guidelines for handling and unpacking the diode to avoid unnecessary damage.

Don’t Over-Apply Grease

While applying grease can improve thermal contact, excessive application can lead to contamination and cause performance degradation. Only apply a thin layer of non-silicone grease. Excess grease can also spread onto other sensitive areas of the device, leading to contamination and potential damage.

Don’t Overtighten or Underrighten Screws

Over-tightening screws can lead to thread stripping, warping of the diode housing, and other mechanical issues. On the other hand, under-tightening can cause loose connections, improper thermal contact, and mechanical instability. Always ensure that screws are tightened correctly and follow torque specifications where available.

Don’t Forget to Inspect Electrical Connections

Electrical connections must be secure and well-soldered to prevent power loss and ensure consistent performance. A weak or poorly connected electrical circuit can cause a variety of issues, including intermittent operation, overheating, or even permanent damage to the diode. Always inspect the connections carefully and ensure that the proper wire size and connectors are used.

Troubleshooting Common Laser Diode Mounting Issues

Misalignment of the Laser Diode

Misalignment can lead to poor coupling efficiency, especially in fiber-coupled systems. To check for misalignment, use precision alignment tools and make adjustments as necessary. Ensuring that the diode is correctly positioned relative to the optical fiber or other components is essential for efficient light transmission.

Poor Thermal Contact

Signs of poor thermal contact include overheating, erratic laser output, or a diode that operates outside of its specified temperature range. If thermal contact is inadequate, recheck the flatness of the mounting plate and consider reapplying thermal grease or using better thermal management solutions.

Electrical Connection Problems

Intermittent or poor performance can often be traced back to issues with electrical connections. Ensure all connections are secure, and the correct wire gauge is used. Inspect soldering points for any signs of corrosion or weakness, and replace connectors if necessary.

Best Practices for Maintaining Your Laser Diode Setup

Regular Inspection and Cleaning

To ensure the continued performance of your laser diode, regular inspections are essential. Check the alignment, thermal contact, and electrical connections periodically to ensure everything is functioning correctly. Clean the mounting surface and diode with appropriate tools, ensuring no contaminants damage the components.

Avoid Contaminants and Electrostatic Discharge (ESD)

Laser diodes are sensitive to both airborne contaminants and electrostatic discharge. Always use anti-static wristbands, mats, and ESD-safe tools when handling the diode. Store the diodes in anti-static packaging to protect them from static electricity, which can cause irreversible damage.

Conclusion

Properly mounting a laser diode is a critical step in ensuring that it functions efficiently and lasts as long as possible. By following the do’s and don’ts outlined in this guide, you can avoid common mistakes and enhance the performance of your laser diodes. Always remember to follow manufacturer recommendations and take the time to mount the diode carefully. Proper installation will prevent future issues and contribute to the success of your laser applications.

FAQs

Q: What is the best way to mount a laser diode?

A: Ensure a flat surface, use the correct screws, and apply thermal grease only when necessary. Always follow manufacturer guidelines.

Q: Can I use any screws to mount a laser diode?

A: No, the screw size must match the mounting pattern to ensure secure attachment and optimal thermal contact.

Q: How do I prevent thermal shock when unpacking a laser diode?

A: Let the diode sit at room temperature for several hours before unpacking to avoid thermal shock.

Q: Is grease necessary for mounting a laser diode?

A: Grease is recommended for higher-power diodes. Apply a thin layer of non-silicone grease to improve thermal contact.

English

English