You need a driver for your laser diode. It gives exact control of current. It keeps the device safe. It lets you use special features. Basic power supplies cannot do this. The driver keeps the output steady. It stops dangerous jumps in current. In a Laser Diode Butterfly Package, there are built-in electronics. These include clipping current limits and slow start circuits. They make the device more reliable.

| Safety Feature | Benefit |

| Clipping current limit | Stops output current from going too high |

| Slow start circuit | Raises output current slowly to stop spikes |

Automated test equipment helps you get better reliability. Careful device checks also help in tough places.

Key Takeaways

A laser diode driver controls the current very carefully. This keeps the laser working well and stops damage from sudden changes in current.

A butterfly package with a driver makes the laser safer. It has safety parts like slow-start circuits and over-current protection.

Drivers can switch on and off very fast. This lets the laser work quickly, which is good for high-speed jobs in telecom and photonics.

Drivers have special ways to control heat. This keeps the temperature steady, which helps the laser last longer and work the same every time.

You should pick a driver with a butterfly package for the best safety and performance. This is extra important for jobs that need careful control.

Current Control

Laser diodes need very careful current control to work right. You cannot use a basic power supply because it does not keep the current steady. A laser diode driver gives the exact current the device needs. This control helps the laser work well and stay safe. The butterfly package for laser diodes has special electronics. These help you set and keep the right current.

Precision

You need to be exact when using a laser diode. Even tiny changes in current can change the light’s color and strength. For example, if you set the current to 50 mA, a good driver keeps it between 49.9928 mA and 50.0065 mA. The current only changes by about 0.0274%. With this control, the light stays the same color and power.

Note: In optical communications, the wavelength must stay very close to a set value. Some systems need it to stay within 3 GHz. Most regular laser diodes cannot do this without a great driver.

A butterfly package helps you get this exact control. It uses an adjustable current source and a control system. These work together to keep the current at your chosen level. The package also has a limit circuit to stop the current from getting too high.

| Component | Function |

| Adjustable Current Source | Gives the exact current you set for the laser diode |

| Control System | Lets you pick current limits and setpoints |

| Error Generation | Checks if the current matches your setpoint and fixes it |

| Limit Circuit | Stops the current from going above safe levels |

| Safety Features | Adds time delays and locks for extra safety |

Output Stability

Steady current means steady output. If the current changes, the laser diode’s color and power will change too. This can hurt how it works and even break it. A good driver keeps the current steady, even if the temperature or power supply changes. The butterfly package has circuits that block noise and stop sudden jumps.

Using a high-quality driver lowers the chance of power changes. This keeps the color and power steady. For example, if the current changes by just 1 mA, the color can shift by about 0.00485 nm. Even small changes matter in sensitive jobs. The butterfly package helps keep things stable, even when the temperature goes up or down.

Tip: Always use a laser diode driver with a butterfly package for the best results. This setup protects your device and keeps your output steady.

Protection Features

Laser diodes are very sensitive. They need strong protection to stay safe. Good protection helps them last longer. The laser diode butterfly package gives many layers of defense. These features stop damage from electrical problems and tough places.

Electrical Safety

Laser diodes must be safe from electrical dangers. Drivers use special safety circuits for this. Here are some common protection features:

| Protection Feature | Description |

| Slow-start circuits | Slowly raise current to stop sudden surges. |

| Over-current protection | Stops too much current from hurting the diode. |

| Over-voltage protection | Blocks extra voltage from reaching the diode. |

| AC transient protection | Guards against power surges from the wall plug. |

| LD current limit | Keeps current at safe levels for the laser diode. |

| Power line transient protection | Shields the diode from voltage spikes in the power line. |

| Monitor photodiode current limit | Makes sure the monitor photodiode does not get too much current. |

| Compliance voltage limit | Stops output voltage from going above safe limits. |

| Output power level limit | Caps the highest output power to protect the diode. |

| TEC current limit | Limits current to the thermoelectric cooler (TEC). |

| High and low temperature limits | Keeps the device working only in safe temperatures. |

| Sensor open detection | Finds if a sensor is disconnected and stops unsafe operation. |

| TEC open detection | Finds if the TEC is not connected and prevents damage. |

Note: Voltage and current limits keep your laser diode safe. They shut down the device if levels get too high. This stops dangerous spikes before they hurt the diode.

The butterfly package uses a monitor photodiode. This part checks the light output. It helps the driver change the current. This makes the laser diode work safely and stay stable.

Failure Prevention

You want your laser diode to last a long time. The butterfly package helps stop common failures. Hermetic sealing keeps out water, dust, and gases. This seal protects the laser diode from the environment. It helps the diode last longer. The glass-to-metal seal is very strong. It keeps the inside clean and dry.

The thermoelectric cooler (TEC) keeps the temperature steady. If the diode gets too hot or cold, the TEC changes the temperature. This stops the diode from overheating. It keeps the laser working well.

Here are some common failure modes and how the package helps:

| Failure Mode | How the Package Helps Prevent It |

| Overdriving the laser | Current and voltage limits stop too much power from reaching the diode. |

| Reverse polarity | Circuit design prevents damage from wrong connections. |

| Power surges and fluctuations | Surge protection and slow-start circuits keep the current steady. |

| Reverse current spikes | Protection diodes block harmful spikes. |

| Current spikes during operation | Slow-start and shutdown features avoid sudden jumps in current. |

The butterfly package also resists shocks and vibration. The strong case and sealed design protect the diode from bumps and drops. You can use these packages in tough places without worry.

Tip: Always pick a laser diode butterfly package for the best protection. You get electrical safety, shielding from the environment, and steady performance.

Modulation and Control

Laser diode drivers do more than give power. They help you control your laser in real time. This control lets your butterfly package work its best. You can turn the laser on and off fast. You can also change how strong the laser is. These features are important for fast and accurate jobs.

Fast Switching

Fast switching helps send data or make laser pulses. A good driver turns the laser on and off quickly. This speed matters in telecom and photonics. Direct modulation can reach a few GHz. External modulation can go up to 100 GHz. High speeds let you send more data and keep signals clear.

The butterfly package works well at these fast speeds. It keeps the temperature steady and protects the laser. This helps keep the wavelength and power the same. You get better results and fewer mistakes.

Tip: Pick a driver with a butterfly package for high-speed jobs. You will get steady operation and less signal loss.

Power Adjustment

You may need to change the laser’s power for different jobs. The driver lets you do this very accurately. You can set the current to get the power you want. The adjustable current source gives you fine control. Feedback from the laser or monitor photodiode helps keep power steady.

Adjustable current source gives precise power control

Feedback keeps optical power constant

Stable power means better performance in changing conditions

This steady power helps keep the wavelength and output stable. The butterfly package uses cooling to keep the device safe. Cooling stops changes in wavelength and power. You get reliable results every time.

Note: Always use a driver with power adjustment features. You will get better results and your device will last longer.

Laser Diode Butterfly Package

Integrated Electronics

A laser diode butterfly package gives you special features. It has built-in electronics that help your laser work better and last longer. These electronics keep the temperature steady, block noise, and watch how the laser is doing.

The package uses a thermoelectric cooler (TEC) to control heat. The TEC keeps the temperature from changing too much. Mechanical isolation stops vibrations from hurting the diode. Electrical shielding keeps outside noise away. This helps your laser work without problems. Real-time monitoring uses photodiodes and thermistors. They check the power and temperature all the time. The system can change settings fast if something is wrong.

| Feature | Description |

| Thermal Management | TEC keeps temperature steady and stops overheating. |

| Mechanical Isolation | Protects against vibrations for stable operation. |

| Electrical Shielding | Blocks outside electrical noise for better performance. |

| Real-time Monitoring | Photodiodes and thermistors track power and temperature for quick response. |

Monitor photodiodes in the butterfly package help you watch your laser’s output. For example, a package might use an 830nm wavelength and give 600mW power. The monitor photodiode can measure up to 2000 μA. You can see changes quickly and adjust the current to keep your laser safe.

Reliability

You want your laser diode to last a long time. The butterfly package helps make it reliable. It uses strong materials and smart design to protect the diode. It keeps the diode safe from heat, shocks, and electrical problems. You get more features in a small package. This saves space and lowers costs.

More features fit into less space.

Using less power helps your device last longer.

Strong materials keep your laser working in tough places.

You get fewer problems and longer life.

The package uses a graphite thermal pad to move heat away fast. This keeps the temperature at the right level. It helps your laser diode stay reliable. The TEC and monitor photodiode work together to control heat and power. You get steady performance even when things change.

Tip: Pick a laser diode butterfly package for the best reliability. You get strong protection, steady output, and long-lasting use.

Application

Laser diode drivers are important in many new technologies. They are used in telecom and photonics. Each job needs careful control, steady output, and good protection. The right driver helps you get the best results every time.

Telecom Use

Laser diode drivers are used in fiber optic networks. These drivers help send data fast and safely. Here are some main ways they are used in telecom:

They power lasers that send data through optical fibers.

They keep laser signals steady and modulated to protect data.

They control many laser outputs at different wavelengths in DWDM systems. This lets you send many data streams on one fiber.

In telecom, you need steady temperature and good thermal management. This keeps the laser wavelength steady and stops signal loss. A good driver helps you avoid mistakes and keeps your network working well.

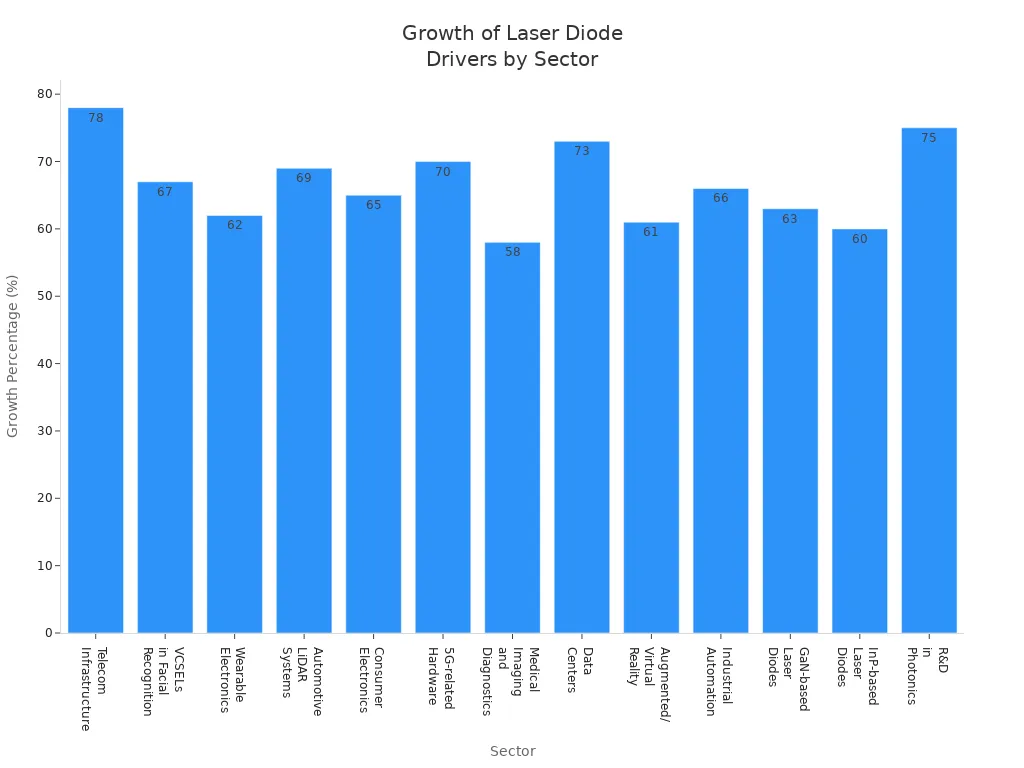

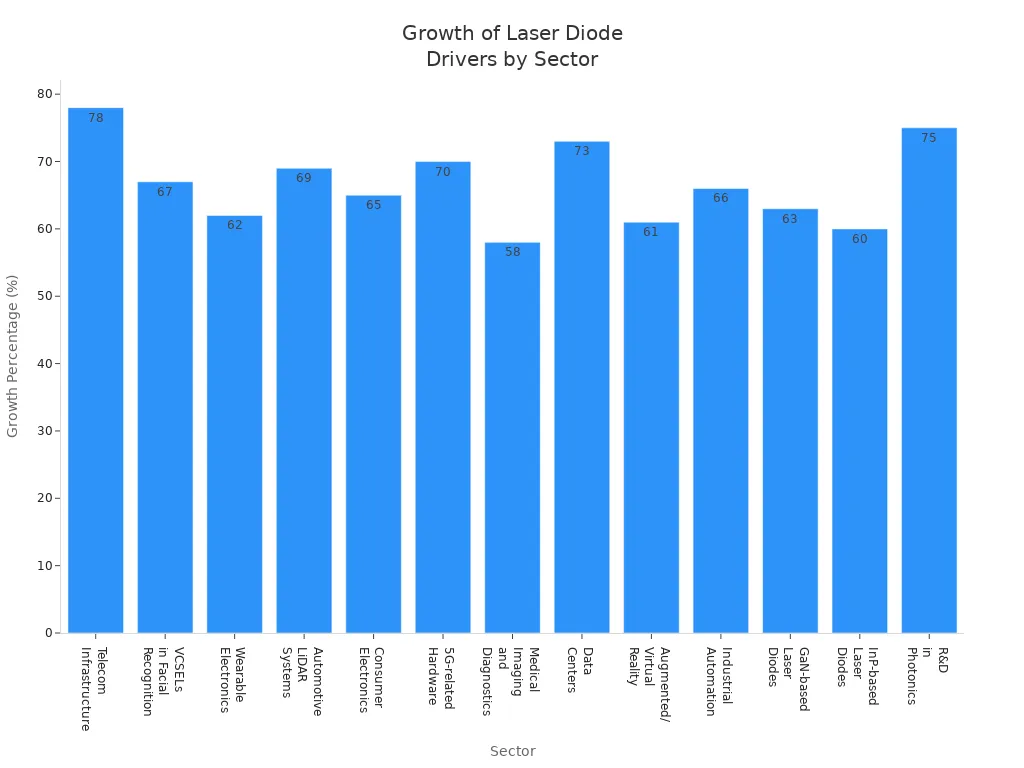

There is more need for advanced drivers in telecom now. The chart below shows how much the need for these drivers is growing in different areas:

Photonics

In photonics, laser diode drivers are used for sensing and measuring. Each job needs special features to work well and stay safe. The table below shows how drivers help in these advanced uses:

| Feature | Description |

| Current Supply | You get the right current for each job, as the laser data sheet says. |

| Noise Management | Low-noise drivers help you get clean, high-quality optical output. |

| Independent Isolation | You avoid damage from ground loops with electrical or optical isolation. |

| Slow Power-On Capability | You protect the laser by starting up slowly, which lowers thermal stress. |

| High-Speed Voltage Limits | You keep the laser safe by shutting down fast if voltage gets too high. |

| Intermittent Contact Safeguard | You stay safe because the driver powers down if it finds a bad connection. |

| Current Limit Features | You keep current within safe limits, which protects your system. |

| Constant Optical Power Mode | You use feedback from a photodiode to keep optical power steady, even if temperature changes. |

You use these features in many photonics jobs, like medical imaging, LiDAR, and industrial automation. Each one needs careful control of temperature and power. Good thermal management helps you get reliable results every time.

Tip: When you pick a driver for any job, make sure it has strong temperature control and thermal management. This will help your system last longer and work better.

You need a laser diode driver to protect your device. Drivers help keep things safe and steady. They control current and temperature. This stops damage from electrical noise. Your laser works well and lasts longer. The butterfly package is small and easy to use. It has strong heat control and connects to fiber easily. You can use it in telecom and photonics. When you choose a driver, look at the current range. Check the pulse width and frequency too. Make sure it has the features you need.

FAQ

What makes a laser diode driver important for high-precision applications?

A driver keeps the current steady. This helps the wavelength and power stay stable. Fiber optics and other precise jobs need exact control. You get better results and fewer mistakes in your work.

How does advanced thermal management improve laser diode performance?

Performance gets better when temperature does not change much. Advanced thermal management uses cooling to keep the laser diode cool. Your device works longer and the wavelength stays the same.

Why do applications need stable power from a laser diode driver?

Stable power helps your device work well every time. If power changes, your device might not work right. A good driver keeps power steady. This gives you the best results in every job.

Can I use a basic power supply for my application instead of a driver?

You should not use a basic power supply. It cannot keep current or power steady. Your device will not work well. You might damage the laser diode and lose control of the wavelength.

How does a butterfly package help in different applications?

A butterfly package gives strong protection and better results. It uses advanced cooling to keep things safe. Your device gets steady power and wavelength in every job.

English

English